Seven commonly used medical Plastic Raw Materials, PVC actually ranked first!

Compared with glass and metal materials, the main characteristics of plastics are: 1, the cost

A seamless, one-stop production system solution.

Supplying quality Medical Components and Products

Guaranteeing consistent and reliable product quality.

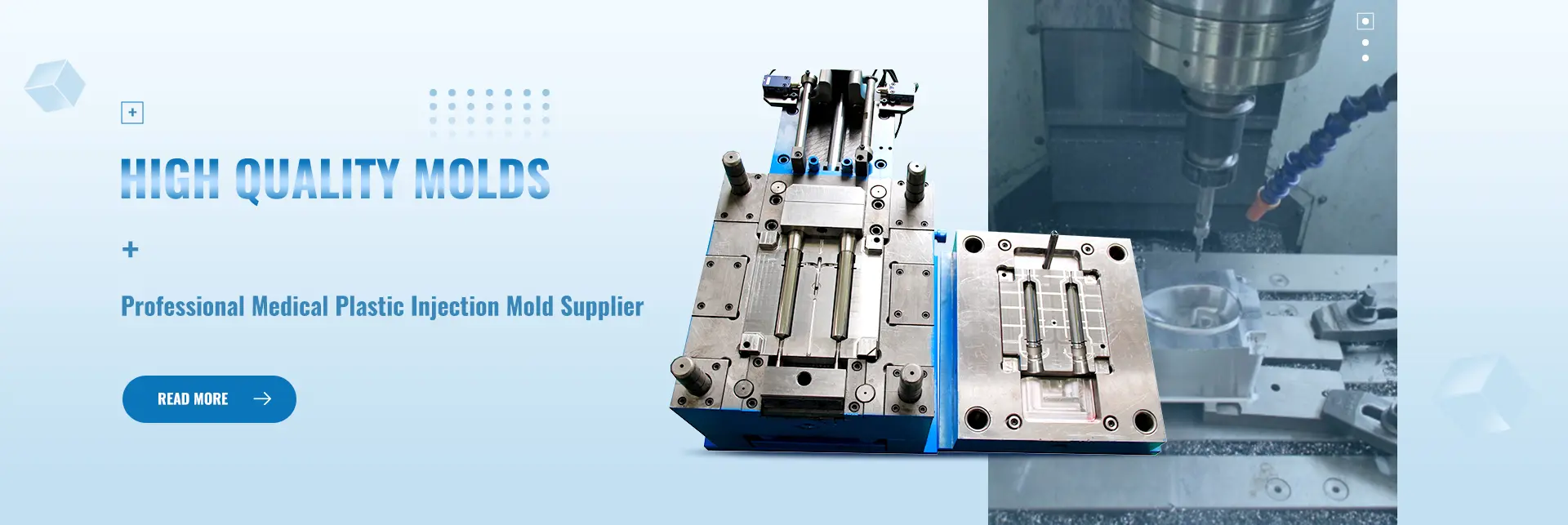

Ningbo Wellmedlab Co., Ltd. is a Chinese manufacturer since 1996 .

We specialize in medical plastic injection molds, medical plastic components and medical consumables manufacturing system solutions , We own 3,000 square meter Class 100,000 purification workshop workroom and 5pcs CNC from Japan/China, 6pcs EDM from Japan/China, 2pcs Wire Cutting from Japan, some Drilling, Grinding, Lather, Milling and 17pcs injection machine and so on.

We specialize in manufacturing precision medical injection molds. Our core products encompass critical components for respiratory & anesthesia (e.g., masks, breathing circuits), infusion & transfusion (e.g., stopcocks, lines), hemodialysis (e.g., bloodlines, needles), and general devices (e.g., syringes, speculums). We also accept custom mold designs.

Instruction: remove and smooth sprue,

Reason: because PVC easy cause to mold rust, which is caused to this question. so When we restart to use molds after a long time. We must check if there are rust in Sprue.

Instruction: elongate the ejection pin distance.

Instruction: Reduce diameter 0.02~0.05mm.

Instruction:

1) Choose Transparent ABS.

2) Increase outside size of cavity gate.

Instruction: Pin of hole is broken, Change the pin.

Instruction: Drill a small pit on the core like the below.

Compared with glass and metal materials, the main characteristics of plastics are: 1, the cost

According to the medical device market analysis report released by YH research, this report provides

I. Basic design ideas: According to the basic requirements of plastic parts and plastic process