Faqs

- Home

- Faqs

Frequently Asked Questions

PVC raw materail is broken in sprue during test TP filter mold.

Instruction: remove and smooth sprue,

Reason: because PVC easy cause to mold rust, which is caused to this question. so When we restart to use molds after a long time. We must check if there are rust in Sprue.

Pin doesn't get out raw material tree during injection.

Instruction: elongate the ejection pin distance.

Sprue is very hard to get out

Instruction: Reduce diameter 0.02~0.05mm.

Cavity gate is broken when Nebulizer cup is produced by PS.

Instruction:

1) Choose Transparent ABS.

2) Increase outside size of cavity gate.

A small is closed in the middle of nebulizer cup.

Instruction: Pin of hole is broken, Change the pin.

Funnel of nebulizer is sitcked on cavity.

Instruction: Drill a small pit on the core like the below.

More details

FAQ1

Question: PVC raw materail is broken in sprue during test TP filter mold.

Instruction: remove and smooth sprue,

Reason: because PVC easy cause to mold rust, which is caused to this question. so When we restart to use molds after a long time. We must check if there are rust in Sprue.

Instruction: remove and smooth sprue,

Reason: because PVC easy cause to mold rust, which is caused to this question. so When we restart to use molds after a long time. We must check if there are rust in Sprue.

FAQ2

Question: pin doesn’t get out raw material tree during injection.

Instruction: elongate the ejection pin distance.

Instruction: elongate the ejection pin distance.

FAQ3

Instruction: Screw hardly yellow plastic hook on the bottom of molds.

FAQ4

Question: Sprue is very hard to get out

Instruction: Reduce diameter 0.02~0.05mm.

Instruction: Reduce diameter 0.02~0.05mm.

FAQ5

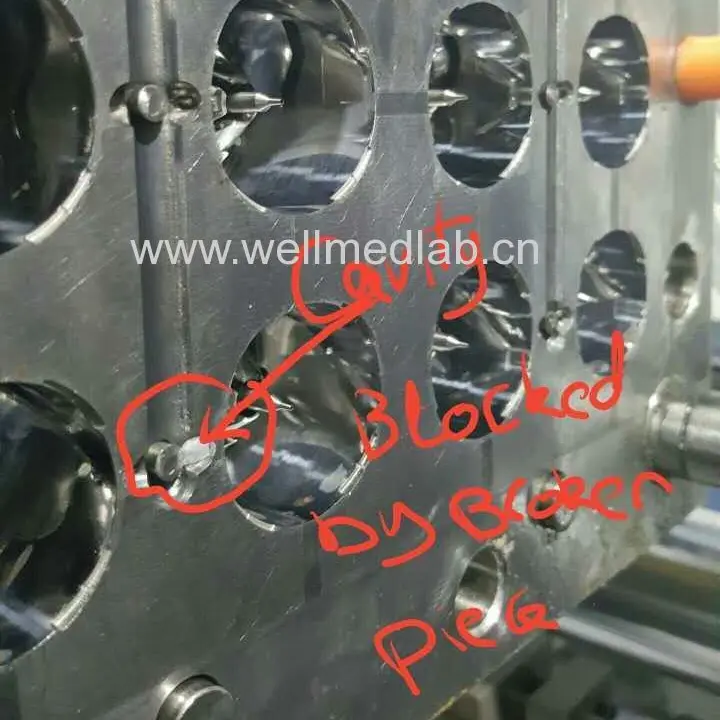

Question: Cavity gate is broken when Nebulizer cup is produced by PS.

Instruction:

1) Choose Transparent ABS.

2) Increase outside size of cavity gate.

Instruction:

1) Choose Transparent ABS.

2) Increase outside size of cavity gate.

FAQ6

Question: a small is closed in the middle of nebulizer cup.

Instruction: Pin of hole is broken, Change the pin.

Instruction: Pin of hole is broken, Change the pin.

FAQ7

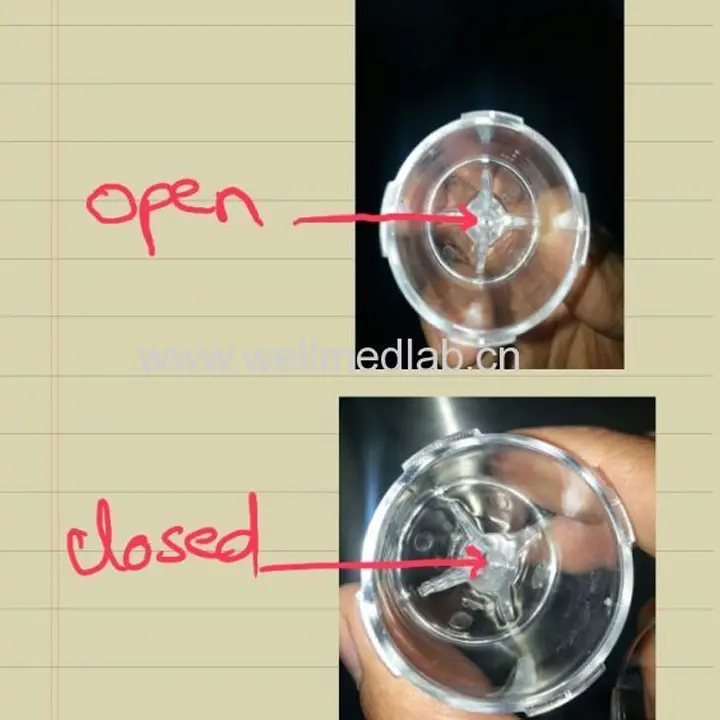

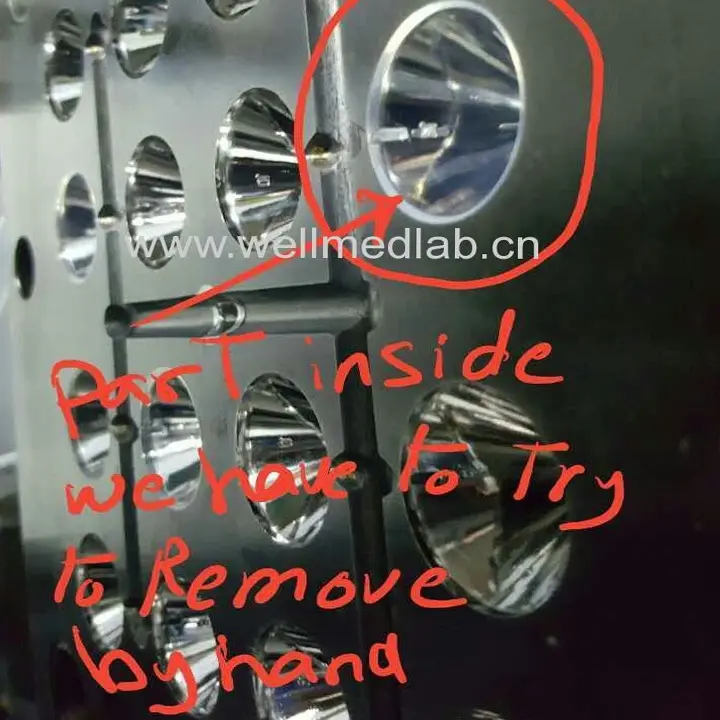

Question: Funnel of nebulizer is sitcked on cavity.

Instruction: Drill a small pit on the core like the below.

Instruction: Drill a small pit on the core like the below.

FAQ8

Question: There are burn point on adaptor.

Instruction: Clear flow way.

Instruction: Clear flow way.

FAQ9

Question: Yellow hook is cutted a small.

Instruction: Smooth hole according.

Instruction: Smooth hole according.

FAQ10

Question: There are flash oxygen mask

Instruction: It is caused because Molds is not closed perfectly. Clear the groove and screw hardly guide pin.

Instruction: It is caused because Molds is not closed perfectly. Clear the groove and screw hardly guide pin.

FAQ11

Question: Pin is gotten out.

Instruction: Knock the pin like the below pictures, so that pin is a little distortion an then pin can be fixed.

Instruction: Knock the pin like the below pictures, so that pin is a little distortion an then pin can be fixed.

FAQ12

Question: Mould can’t be closed during test TP filter mould

Instruction: improve matching during guid pin and guid hole.

Instruction: improve matching during guid pin and guid hole.

FAQ13

Question: some PVC adaptor is sticked on the cavity.

Instruction:

1. checking if Cooling water is OK

2. sand these cavities directly a small rough by 240S sand paper, which is not effected surface.

Instruction:

1. checking if Cooling water is OK

2. sand these cavities directly a small rough by 240S sand paper, which is not effected surface.

FAQ14

Question. There are some flash.

Instruction: First cover red inkpad on ” A ” of covities. and close mold to check red mark. and then repair ” A ” accordingly.

Instruction: First cover red inkpad on ” A ” of covities. and close mold to check red mark. and then repair ” A ” accordingly.

FAQ16

Question: There are some white dots on nebulizer cup

Insstruction: Maybe when switching cooling water tube. Some water are splashed on nebulizer cup. It cause to some rust on mold. these rust cause to white dots. remove these rust by the below tool.

Insstruction: Maybe when switching cooling water tube. Some water are splashed on nebulizer cup. It cause to some rust on mold. these rust cause to white dots. remove these rust by the below tool.